In the era of rapid technological advancement, businesses are under increasing pressure to optimize their physical assets and processes in real time. Enter Digital Twins—a breakthrough innovation that bridges the physical and digital worlds to revolutionize how we monitor, analyze, and control real-world systems.

Digital twins are not merely visual replicas; they are dynamic, intelligent simulations powered by real-time data, artificial intelligence (AI), and machine learning (ML). This technology offers actionable insights that can lead to better decision-making, operational efficiency, cost savings, and innovation across numerous industries.

In this comprehensive guide, we’ll explore everything you need to know about digital twins: what they are, how they work, their core components, benefits, use cases, industries being transformed, challenges, implementation tips, and the future outlook—all optimized to boost search engine visibility and monetization.

What Are Digital Twins?

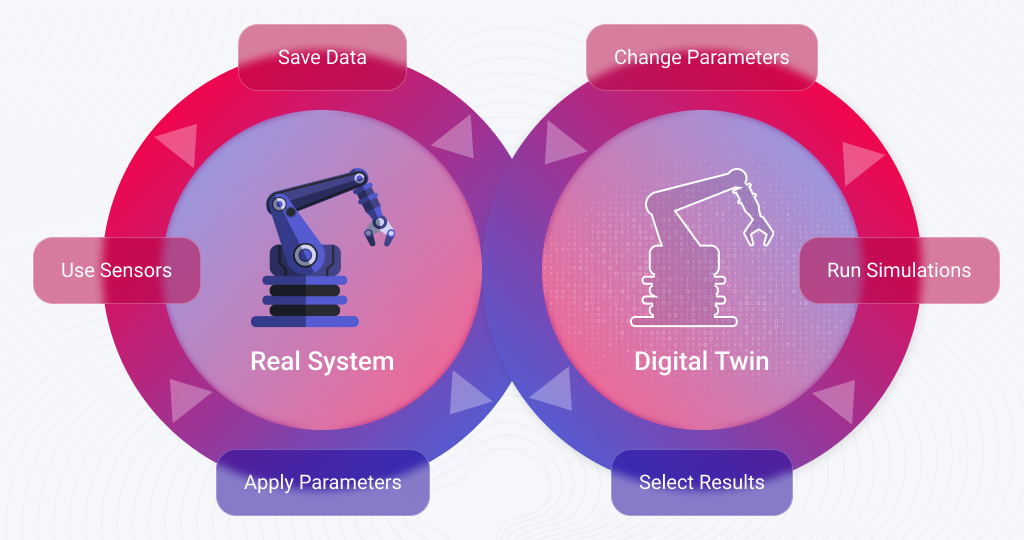

A digital twin is a virtual representation of a physical object, system, or process that is continuously updated with real-time data. This digital model reflects the status, working condition, and behaviors of its real-world counterpart, allowing for simulations, performance monitoring, prediction, and control.

Unlike traditional simulations, digital twins are live, data-connected models that evolve and improve over time.

Core Components:

A. Physical Entity – The object or system being mirrored (e.g., a wind turbine, factory line, or human body)

B. Digital Replica – The 3D model or software-based version that replicates the physical system

C. Data Connectivity – Real-time sensor data and IoT feeds that update the twin

D. Analytics Engine – AI/ML algorithms that analyze incoming data

E. Visualization Interface – Dashboards or 3D displays to interact with the twin

F. Feedback Loop – The ability to control or adjust the physical system based on insights

How Do Digital Twins Work?

Digital twins work by creating a loop of continuous interaction between physical and virtual worlds.

A. Data Collection

Sensors, IoT devices, GPS trackers, and cameras collect real-time operational data from physical assets.

B. Data Integration

This data is fed into the digital twin via cloud computing platforms or edge devices, enabling the virtual model to mirror real-time conditions.

C. Simulation and Modeling

The digital twin uses physics-based and data-driven models to simulate behavior, predict failures, and recommend improvements.

D. Insights Generation

AI and machine learning analyze the data to detect patterns, forecast outcomes, and suggest actions.

E. Decision Making

Stakeholders or autonomous systems act on recommendations to optimize performance, reduce downtime, and enhance productivity.

F. Continuous Learning

As more data flows in, the twin becomes smarter, adapting to new conditions and increasing its predictive accuracy.

Types of Digital Twins

There are various classifications depending on complexity and function:

A. Component Twins

Digital replicas of a single part or component, such as a motor or pump.

B. Asset Twins

These combine multiple components to simulate a complete piece of equipment, like an engine or robotic arm.

C. System Twins

They replicate entire systems made of several interconnected assets—for example, an assembly line or HVAC system.

D. Process Twins

These simulate end-to-end workflows like supply chain logistics, hospital patient flows, or urban traffic control.

E. Organizational Twins

The most complex, modeling how departments, people, and workflows interact across a business or city.

Benefits of Using Digital Twins

Digital twins offer tremendous advantages across various areas:

A. Real-Time Monitoring

They provide live dashboards to track performance, energy usage, health status, and operational status.

B. Predictive Maintenance

By spotting early signs of wear or malfunction, digital twins reduce unplanned downtimes and save repair costs.

C. Process Optimization

They test process changes virtually before physical implementation, lowering risks and maximizing output.

D. Cost Efficiency

Better decision-making leads to reduced waste, energy usage, and manual intervention.

E. Faster Innovation

Engineers and designers can test new ideas in simulations without disrupting real operations.

F. Improved Safety

By simulating hazardous environments, digital twins reduce exposure risks for workers and improve emergency planning.

G. Sustainability

They help optimize resource usage and carbon footprint by analyzing environmental impacts.

Real-World Applications of Digital Twins

Let’s explore how different industries are using digital twin technology to solve real-world challenges.

1. Manufacturing

-

Simulate assembly lines to improve throughput

-

Monitor machine performance to reduce downtime

-

Test new product designs before prototyping

2. Healthcare

-

Personal digital twins simulate patient responses to treatments

-

Real-time monitoring of implants and wearable devices

-

Optimizing hospital workflows and resource allocation

3. Smart Cities

-

Simulate traffic flows, utilities, and infrastructure loads

-

Predict equipment failures in public services

-

Plan urban growth with energy modeling and pollution data

4. Automotive and Aerospace

-

Create digital twins of vehicles and aircraft for safety tests

-

Monitor engine performance remotely

-

Improve design with in-flight and on-road data feedback

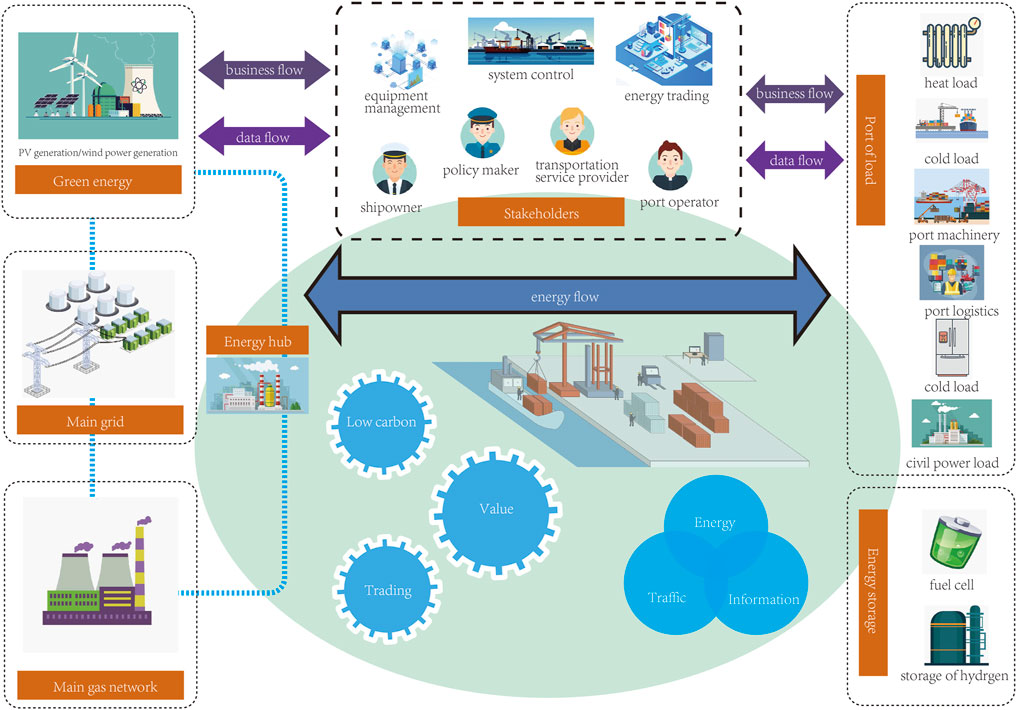

5. Energy & Utilities

-

Optimize wind turbines, solar panels, or grids in real time

-

Predict failure in oil rigs or pipelines

-

Manage distributed energy systems with real-time analytics

6. Construction and Real Estate

-

Model buildings before construction to reduce errors

-

Use BIM (Building Information Modeling) in conjunction with digital twins

-

Monitor structural health and energy efficiency over time

7. Logistics and Supply Chain

-

Predict disruptions and reroute shipments

-

Analyze warehouse efficiency

-

Manage fleet performance using digital twin of vehicles

Key Technologies Powering Digital Twins

A. Internet of Things (IoT)

Sensors and devices connect the physical world to digital platforms.

B. Artificial Intelligence (AI)

AI analyzes complex data and drives decision-making through intelligent algorithms.

C. Machine Learning (ML)

ML refines predictions and adapts simulations over time.

D. Cloud and Edge Computing

They handle massive data processing and allow remote access to digital twins.

E. AR/VR Integration

Visualize digital twins through immersive technologies for better training and diagnostics.

F. 5G Connectivity

Ultra-fast networks enable real-time updates with minimal latency.

Implementation Challenges

Despite its potential, deploying digital twins isn’t without obstacles.

A. Data Silos

Scattered or non-integrated data makes it difficult to create comprehensive models.

B. High Initial Cost

Building and deploying digital twins requires substantial investment in hardware, software, and expertise.

C. Cybersecurity Risks

More connectivity increases vulnerability to cyberattacks or data breaches.

D. Skill Gaps

Few professionals have expertise in IoT, AI, simulation, and systems integration simultaneously.

E. Interoperability

Different systems and platforms often don’t talk to each other seamlessly.

F. Scalability

As models grow, maintaining performance and accuracy becomes harder.

Best Practices for Deploying Digital Twins

A. Start Small

Begin with a pilot project like a single machine or process before scaling.

B. Define Clear Goals

Align your digital twin strategy with business objectives (e.g., cost savings, efficiency, safety).

C. Use Modular Architecture

Design your twin in components to allow flexibility and easier upgrades.

D. Ensure Data Quality

Poor data results in inaccurate models. Clean, validated data is essential.

E. Collaborate Across Departments

Involve IT, operations, and business units from the start to avoid misalignment.

F. Invest in Cybersecurity

Protect both the digital twin and the physical asset from digital threats.

G. Choose the Right Platform

Use scalable, open, and customizable platforms that support AI and IoT integrations.

The Future of Digital Twins

Digital twin technology is still evolving. Expect rapid advancements in the coming years.

A. Autonomous Twins

They will self-correct based on real-time data without human input.

B. AI Co-Pilots

AI will act as assistants, offering automated insights and actions to decision-makers.

C. Blockchain Integration

Secure and verify data exchanges between multiple twins or organizations.

D. Industrial Metaverse

A convergence of digital twins and AR/VR to create fully immersive operational environments.

E. Twin-as-a-Service (TaaS)

Subscription-based digital twin models will become available for small and mid-sized businesses.

F. Cross-Industry Collaboration

Twins from different domains will interact for supply chain, logistics, and ecosystem optimization.

Conclusion

Digital twins represent a transformative leap in how we design, manage, and optimize real-world systems. By creating dynamic, intelligent models fueled by real-time data, businesses gain deeper insights, improve efficiencies, and make smarter decisions.

Whether it’s optimizing a factory floor, designing safer vehicles, or planning smart cities, the digital twin is a versatile, scalable technology poised to reshape our world.

Organizations that adopt this innovation today will be better prepared for tomorrow’s challenges—faster, smarter, and more competitive than ever before.

Tags: